Zhejiang, China Dec 9, 2025 (Issuewire.com) - The modern plastics processing industryencompassing everything from medical devices to automotive componentsrelies fundamentally on the performance of a single, crucial element: the screw and barrel. These components are the thermodynamic heart of every extrusion and injection molding machine, directly determining the quality, stability, and efficiency of the finished product. In a sector rapidly evolving towards high-performance materials and complex recycling processes, the demand for precision-engineered, durable screws and barrels has never been higher.

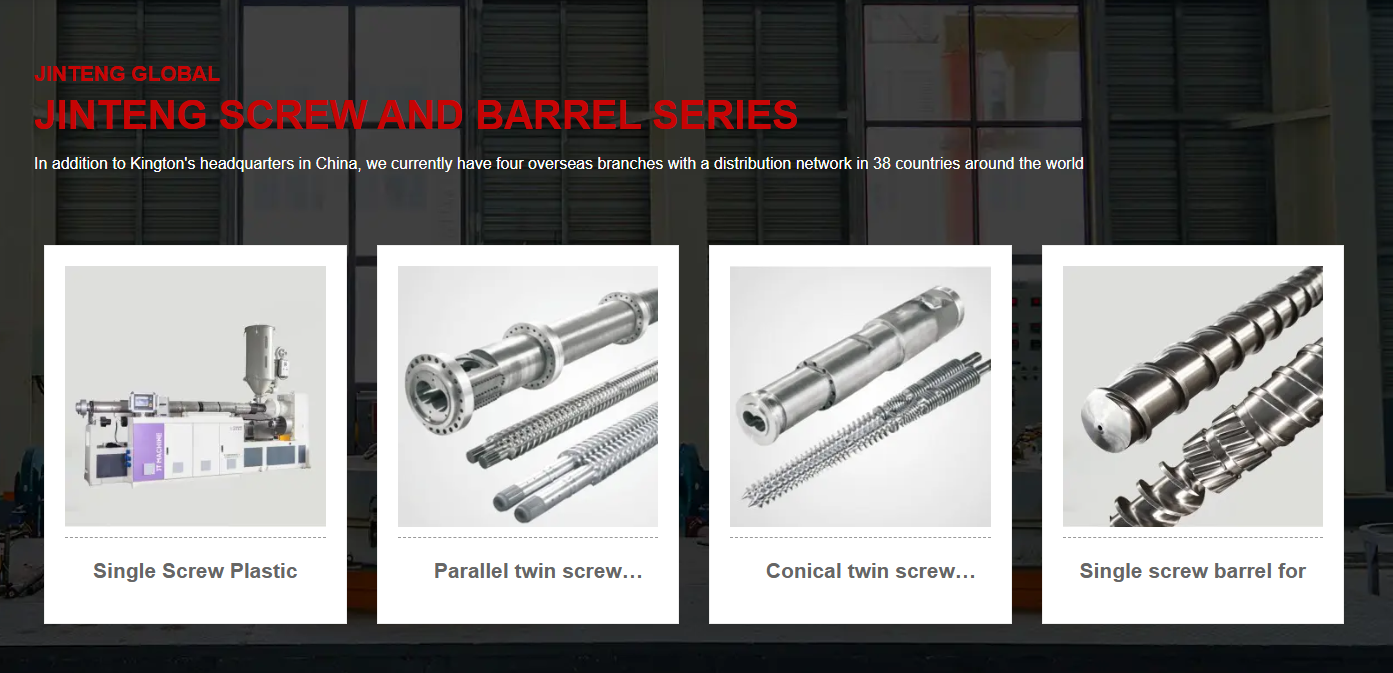

Standing at the confluence of this demand and decades of specialized manufacturing expertise is Zhejiang Jinteng Machinery Manufacturing Co., Ltd. Located in Zhoushan, Zhejiang, a region widely recognized as one of Chinas major bases for polymer machinery component production, Jinteng has successfully established itself as a leading domestic manufacturer. Through rigorous commitment to quality and technical mastery, Jinteng has earned its standing as a premier China Top Screw Barrel Manufacturer. Jintengs success story, spanning over 20 years, is built on an unwavering focus on engineering excellence, state-of-the-art production capabilities, and a global perspective on customer needs.

Core Advantage: The Triad of Expertise, Precision, and Quality

Jintengs competitive edge in the highly specialized screw and barrel market is not derived from volume alone, but from a strategic combination of deep institutional knowledge, continuous investment in advanced technology, and a world-class quality management system.

Engineering Design Mastery

A screw is more than just a metal shaft; it is a meticulously designed tool responsible for melting, mixing, and conveying polymer materials. The performance of the final plastic partits strength, clarity, and consistencyis a direct function of the screws design geometry. Jinteng maintains a skilled design team whose expertise covers a vast spectrum of polymer behavior. This team specializes in custom designs tailored to specific materials, including standard commodity plastics (PE, PP, PVC), challenging engineering polymers (PA, PC, PEEK), and highly specialized applications like rubber and chemical fibers.

Their design mastery focuses on optimizing key parameters such as compression ratio, L/D ratio (length-to-diameter ratio), and the configuration of mixing elements (e.g., Maddock or barrier sections). This precise engineering ensures maximum plasticizing efficiency, minimizes melt temperature fluctuations, and crucially, prevents polymer degradationa common issue when processing sensitive or recycled materials.

Advanced Manufacturing Technology

To translate complex designs into high-precision physical components, Jinteng operates a sophisticated manufacturing base equipped with advanced processing and testing equipment. The production process involves highly specialized steps that dictate the final durability and performance of the components:

Material Selection: Jinteng selects only high-grade alloy steels, such as 38CrMoAlA, tool steels, and specialized powder metallurgy alloys, chosen for their inherent strength and heat-treatment properties.

High-Precision Machining: Utilizing advanced CNC (Computer Numerical Control) machining centers and deep-hole drilling equipment ensures that the screw profile, thread pitch, and barrel bore maintain extremely tight dimensional tolerances. Jinteng can process screw barrels across a wide diameter range, from $\Phi 15 \text{ mm}$ to $\Phi 300 \text{ mm}$, accommodating both small laboratory extruders and large-scale industrial lines.

Surface Treatment and Metallurgy: This is perhaps the most critical stage. Jinteng employs advanced surface treatments like gas nitriding for superior surface hardness and, more importantly, bimetallic spraying for the barrels. The bimetallic process involves centrifugally casting specialized wear-resistant and corrosion-resistant alloys onto the inner surface of the barrel. This metallurgical bond provides exceptional longevity when processing filled polymers (e.g., glass fiber, talc) or corrosive materials (e.g., fluoropolymers, halogenated polymers), substantially extending the component's service life and ensuring stable, high-precision output.

Commitment to Global Quality Standards

Jinteng operates under a complete and internationally recognized quality management system. The companys adherence to global best practices is affirmed by its three key certifications:

ISO 9001 (Quality Management): Ensures consistent production quality and repeatability, guaranteeing that every screw and barrel meets stringent design specifications.

ISO 14001 (Environmental Management): Demonstrates Jinteng's proactive commitment to minimizing its environmental footprint and operating sustainably, a growing requirement for global supply chains.

ISO 45001 (Occupational Health and Safety): Validates the company's commitment to employee safety and health, ensuring a responsible manufacturing environment.

These certifications are essential credentials that build trust with multinational customers, confirming Jintengs capability to supply stable and high-precision products to customers worldwide.

Product Applications and Global Reach

Jinteng's products form the foundation of processing machinery used across virtually every sector of modern industry. Their specialization allows them to cater to diverse and highly demanding applications:

Extrusion Applications

In extrusion, Jinteng supplies screws and barrels for manufacturing continuous profiles. This includes high-performance applications such as:

Pipe and Profile: Used in infrastructure, construction, and window frames (often requiring high-wear resistance for PVC compounds).

Film and Sheet: Critical for packaging, agricultural film, and rigid sheets, demanding extremely high material consistency and low-melt temperature variation.

Wire and Cable: Precision screws are vital for the continuous jacketing of electrical cables, requiring excellent melt homogeneity for insulating layers.

Injection Molding Applications

For injection molding, where rapid cycles and precise shot control are necessary, Jinteng provides complete screw, barrel, and non-return valve assemblies. These components are integral to producing:

Automotive Parts: Components like dashboards, bumpers, and engine parts utilizing engineering plastics and composites.

Consumer Electronics: High-precision casings and internal components for smartphones and computers.

Medical Devices: Producing components requiring exceptionally clean, stable processing, often using specialized resins.

Rubber and Chemical Fiber

Beyond traditional plastics, Jinteng provides customized solutions for the rubber industry (ee.g., mixers and pre-formers) and the chemical fiber industry (e.g., spinning pump components), requiring components designed to withstand unique material viscosities and chemical challenges.

Customer Success and Case Studies

While specific proprietary client names are confidential, Jintengs role can be illustrated through typical customer success scenarios. A global client specializing in high-end electronic casings faced frequent downtime due to premature wear on their barrels when processing abrasive PCABS blends. By switching to Jinteng's bimetallic barrels with a tungsten carbide alloy lining, the client saw their component lifespan increase by over 150%, drastically reducing maintenance costs and improving overall equipment effectiveness (OEE). Another case involved a European pipe manufacturer needing to increase the throughput of recycled high-density polyethylene (HDPE). Jinteng's design team engineered a special barrier screw geometry that efficiently separated solids from the melt, allowing the use of a high percentage of recycled material without sacrificing output or melt quality, thus directly contributing to the clients sustainability goals.

Industry Outlook and Jintengs Strategic Positioning

The future of plastics processing is defined by two powerful forces: sustainability and Industry 4.0. Jinteng is strategically positioned to thrive within both trends.

1. The Circular Economy and Recycling Challenges

The global push toward a circular economy means that manufacturers are increasingly integrating Post-Consumer Recycled (PCR) plastics into their products. Processing recycled materials presents significant challenges: PCR feedstock often contains impurities, varying melt flow rates, and abrasive contaminants (like dirt or grit). These factors accelerate wear on screws and barrels and compromise final product quality. Jintengs expertise in bimetallic and high-alloy metallurgy directly addresses this challenge, providing the durable, corrosion- and wear-resistant components necessary to process challenging recycled materials reliably. This focus makes Jinteng an essential partner for companies committed to meeting new recycling mandates and environmental goals.

2. Industry 4.0 and High-Efficiency Processing

The industry is moving toward "Intelligent Manufacturing," where extrusion and molding lines are equipped with sophisticated sensors and real-time control systems. The ability of these systems to maintain quality relies entirely on the consistency and precision of the mechanical heartthe screw and barrel. Minor thermal or melt variations caused by worn or poorly designed components negate the benefits of sophisticated control software. Jintengs commitment to ultra-high precision engineering ensures that their components provide the stable foundation required for closed-loop control and automated quality management. Furthermore, the capacity to process specialized screws that facilitate rapid melting and compounding supports the industry's continuous demand for higher throughput and reduced energy consumption.

In summary, Jinteng is not merely reacting to market demands; it is anticipating and enabling the future of polymer processing. By combining decades of specialized manufacturing experience in Zhoushan with stringent quality standards and a proactive approach to advanced metallurgy, Jinteng ensures that manufacturers worldwide have access to the most reliable, precise, and durable screw and barrel components available. This allows global customers to confidently pursue higher efficiencies, complex material processing, and critical sustainability objectives.

To learn more about Zhejiang Jinteng Machinery Manufacturing Co., Ltd.'s range of high-precision screw barrels and customized components, please visit their official website:

Website: https://www.zsjtjx.com/

Media Contact

Zhejiang Jinteng Machinery Manufacturing Co., Ltd.

0086-13505804806

No. 98, Zimao North Road, High-tech Industrial Park, Dinghai District, Zhoushan City, Zhejiang Province,China.

Source :inteng Machinery Manufacturing Co., Ltd.

This article was originally published by IssueWire. Read the original article here.